What many people that I talk to often do not understand about painting or finishing, is that most of the time and effort required to obtain great results has less to do with applying the paint, as how well the prep work is done before, and in between, the applications. Simply put, better surface preparation gives you better results in the end.

The photo at the head of the page is a good example of what I'm talking about here. The bar top was made of Ipe wood and after it's construction the real time consuming work of smoothing and sanding began. One works the entire surface with course grade sandpaper and graduates to finer and finer grit papers until a desired smoothness is achieved.

Next, getting all dust and particulates off of the surface and surrounding area is critical. At that point, a sealer can be applied to the wood and left to dry. This will raise the lingen in the grain of the wood slightly, and be absorbed into the grain. When dry, this coat of finish (I used a durable polyurathane floor finish) will be sanded with a fine grit sandpaper to smooth and to allow the next coat of finish to adhere.

The following coats of finish (4 in all) were applied and let dry, wet sanding in between each coat with finer grit sandpapers, as in auto body finishes. For this bar top I hand wet sanded through the available grits up to 1000 grit. As well, all dust was removed in between sanding and finish application and wiped down with fast drying lacquer thinner to remove fine particles. A bit time consuming but the results were worth it.

Exterior And Interior Patching and Painting

Finishing and interior or exterior painting follow the same set of principals as in the example above. Preparation of the surface, removing dust and using the correct product for each step. There are no shortcuts to a good job whether it's a small patch or large room.

My Guarantee to you:

"I will always follow the correct steps to acheive the best result for your job,

and if something is ever not right, I will make it right.

C.L. Simco

,,

Imagine

A Sunset, Rainbow Or Flower

in shades of

BLACK, WHITE AND GRAY

Love Color

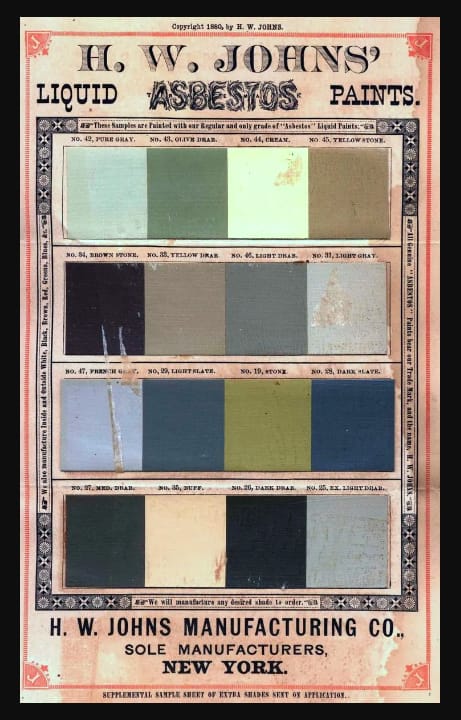

Paint Colors From Long Ago

There were some beautiful and long lasting colors made from natural minerals, however the carriers and other additives made them extremely harmful.

Thank goodness society is finally making progress in creating and offering alternatives to lead based paints and other toxic materials. Who in their right mind would even consider an Asbestos Paint today?

In the early 1970's I recall working for a government contractor painting Red Lead Primer and other increadibly toxic finish coats below decks of an aircraft carrier. These substances were so toxic that air had to be pumped in to these tiny enclosed quarters so that we could even work. And then, only 15 minutes at a time with a 45 minute break to try and clear our heads. Looking back on a time when I was younger and "stupider".

While things are not yet perfect, they are getting better. There are products that are really good and improving while more are coming onto the market as people's awareness of, and demand for, altrnatives grows. More companies that manufacture these products are increasingly finding that as expensive as it is to reformulate and perfect, the transition to newer "green" materials are effective and will insure their success and profitability. A growing "Win, Win".

Here are a couple of links as an introduction, and much more can be learned just by doing a google search for sustainable products.

Eco Friendly Paints and Stains

Green Building And Recycling

At all times, I strive to provide the highest quality workmanship and materials available in accordance with the job requirements of each individual client. I welcome all inquires of any nature gladly, and assure you that I shall endeavor to continually merit your confidence.